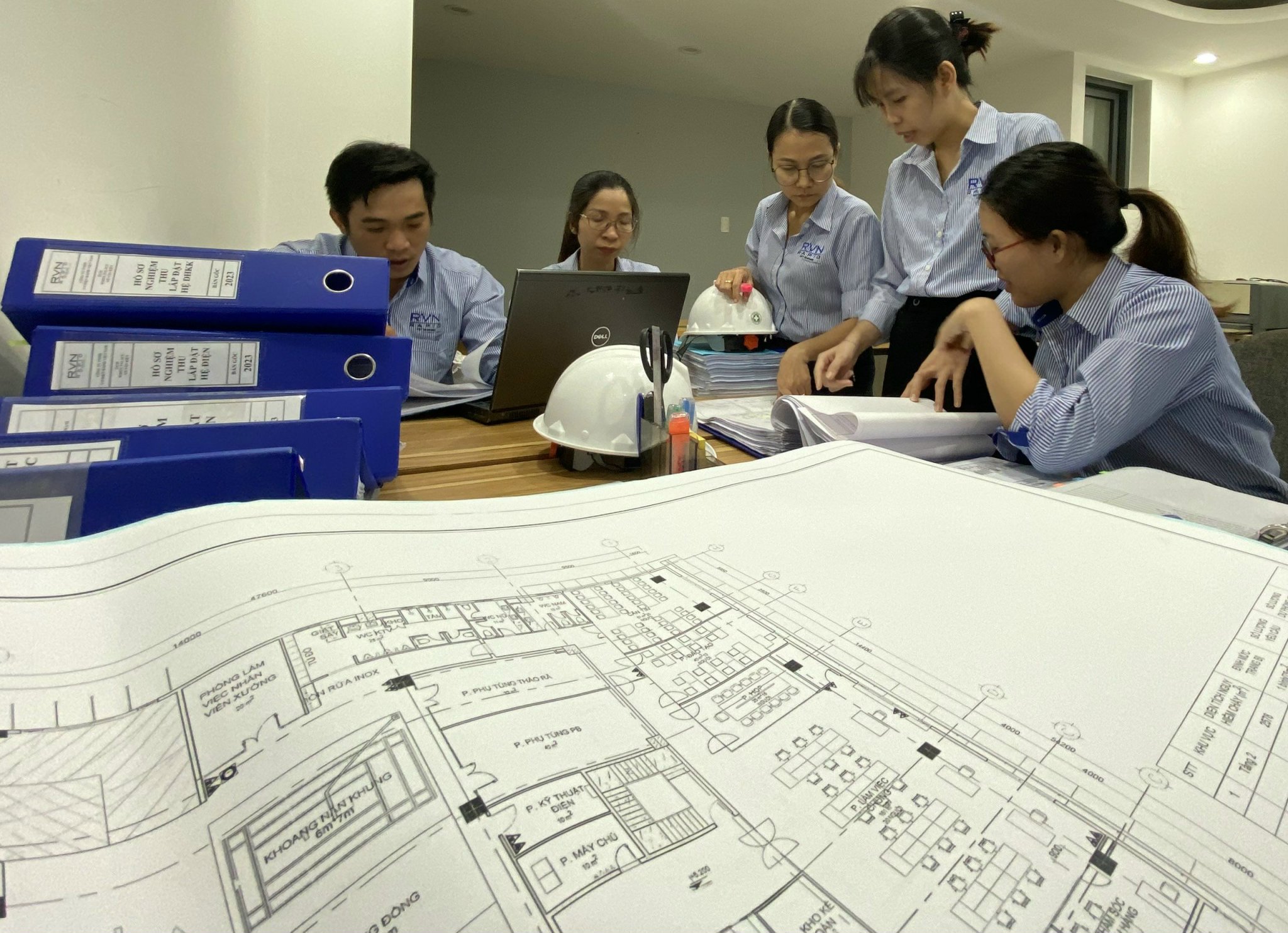

QA/QC in the Mechanical and Electrical Construction Industry And Its Importance

1. Definition of QA and QC

- QA (Quality Assurance): This is the overall management process and procedure to ensure that quality standards and requirements are followed throughout the project. For M&E projects, QA ensures that every step from design, material selection, and installation to system operation complies with strict quality standards.

- QC (Quality Control): This is a specific process that checks and controls the quality of M&E components at each stage. QC involves inspecting and testing finished products or systems to confirm that they meet established standards and specifications.

2. The Importance of QA/QC in the M&E Industry

- Ensuring safety and performance: QA/QC testing helps detect technical errors in the M&E system early, thereby minimizing safety risks and ensuring the system operates stably and efficiently. A substandard M&E system can lead to dangerous incidents, affecting both the project and the user.

- Saving costs: Detecting errors early during installation and operation helps avoid future repair and maintenance costs. A strict QA/QC process will help minimize errors, and waste materials, and save construction time.

- Ensuring legal compliance and reputation: M&E systems must comply with technical standards and legal regulations. Performing QA/QC not only ensures that the system meets quality standards but also ensures full compliance with legal regulations, thereby maintaining the reputation of Rapid Vietnam Mechanical and Electrical Company Limited.

- Optimize project efficiency: QA/QC helps ensure that the mechanical and electrical system is installed and operated optimally, prolonging the life and improving the efficiency of the system. If quality issues are resolved promptly, the system will operate sustainably for a long time.

3. Basic Steps in the QA/QC Process at Rapid Vietnam

- Quality planning: Determine the quality standards and requirements for the mechanical and electrical project, including technical standards, legal regulations, and customer requirements.

- Conduct inspection and testing: Conduct periodic inspections and tests of mechanical and electrical components and systems to ensure that all meet requirements.

- Monitoring and recording: Monitor the progress and quality of the electromechanical system through periodic reports, thereby promptly detecting and handling arising problems.

- Evaluation and improvement: After completing the project, evaluate the overall QA/QC process to find strengths and points that need improvement, thereby drawing experience for future projects.

At Rapid Vietnam M&E CO., LTD, we always strictly and closely follow the QA/QC process in each project. We understand that quality is not only a decisive factor for the success of the project but also a commitment to customers and society. Therefore, we constantly improve and enhance the QA/QC process to ensure that every electromechanical system we design and install meets the highest standards of quality and safety.

QA/QC is not only a part of the electromechanical construction process but also the foundation to ensure the success of each project. Strict application of QA/QC not only protects safety and assets but also helps optimize costs, and time, and maintain a reputation for all parties involved. Rapid Vietnam Mechanical and Electrical Co., Ltd always puts quality first, committed to providing optimal, safe, and sustainable mechanical and electrical solutions for all projects.